Risk Area

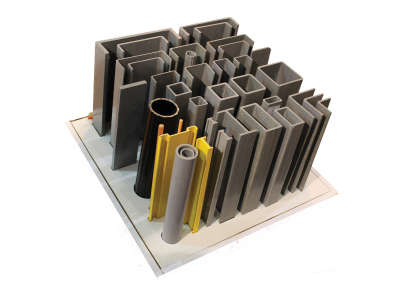

GRP Composites

Real Safety Contact Info:

We are experts in GRP Composite construction materials.

There are known risks assocated with using conventional materials like steel.

Unlike steel, FRP/GRP molded and pultruded gratings are lightweight and strong, and an ideal alternative to conventional steel grates in construction.

The risks when using metal include:

- Oxidation and corrosion

- Deformation

- High electrical and thermal conductivity

- High installation costs due to material weight and galvanization

Above risk factors result in high maintenance costs, especially in coastal and wet environments or where warm and humid temperatures are present.

These risks can be avoided by using Real Safety’s GRP Composite products:

- Unaffected by water and resistant to chemicals

- Non-conductive and insulator to thermal conductivity

- Low installation costs – no use of torches

- Low weight – 1/3 of steel

- GRP Composites will not deform under impact

- Long product life

- Low maintenance costs

Need some help or got a question? Please get in touch.

No Corrosion

No Deformation

Cost Effective

Low Maintenance Costs

Resistant to chemicals

Real Safety Solutions

In many cases, our GRP worksite solutions can replace steel as non-corrosive, yet structurally sound construction materials. As a result, construction and production site risks can be avoided by using Real Safety FRP/GRP solutions.

Take a look at our Water desalination Case Study in Saudi Arabia. This was a project to build eight sea water desalination plants. Several of our GRP products were successfully used in an environment exposed to high levels of corrosion and humidity – and where product quality and performance was extremely important.

Visit our Youtube channel where you can subscribe to our channel – and view more Real Safety solution videos

Case study: Water desalination Project

The Ministry of Environment of Saudi Arabia is building sea water desalination plants in many cities in order to meet daily water needs.

The project consists of eight SWRO desalination plants, spanning the western coast of the Kingdom across a distance of 1,800 km.

Real Safety delivered a range of GRP Profiles for the construction phase.