Construction Industry

Real Safety’s construction industry FRP/GRP solutions are used in both new but also for refurb construction projects.

FRP or GRP Structural pultruded profiles are made by mixing a resin matrix with a fibre reinforcement. Afterwards, this is formed and cured in a continuous process. That creates a product of extraordinary strength and resilience. FRP or GRP profiles provide a variety of benefits and mechanical properties. They clearly match or exceed those made from steel.

Known risks in the construction industry by using conventional materials like steel are:

- Oxidation and corrosion

- Deformation

- High electrical and thermal conductivity

- High installation costs due to material weight and galvanization

- High maintenance costs

These risks can altogether be avoided by using Real Safety FRP solutions. Advantages of using our non-metallic construction materials are:

- Unaffected by water and also resistant to chemicals

- Will not deform under impact

- Non-conductive and also insulator to thermal conductivity

- Low installation costs – no use of torches

- Low weight – 1/3 of steel

- Long product life

- Low or no maintenance costs

As a result, these frp construction products and composites are becoming more popular than traditional materials due to their obvious benefits and durable performance in challenging environments.

CASE STUDY – Saudi Arabia West Coast

Challenge:

The Ministry of Environment of Saudi Arabia is building sea water desalination plants in many cities in order to meet daily water needs. The project consists of eight SWRO desalination plants, spanning the western coast of the Kingdom across a distance of 1,800 km. The consortium, led by Advanced Water Technology Company consisting of four companies: AWT, Rawafid, Al-Fatah and SETE, was chosen to design and implement the project owned by the ‘Saline Water Conversion Corporation’.

Problem:

Obviously, when processing saltwater to water which is suitable for human consumption (desalination), the environment in the processing plant is very humid. As a result, facilities are very exposed to corrosion issues. Damp and the chemical Brine are also present, both of which have a highly corrosive impact especially on steel structures.

Solution:

Real Safety’s FRP solutions were chosen for the 8 plants in Haql, Duba, Al-Wajh, Umluj, Al Shuqaiq, Al–Qunfudhah, Al-Leith and Fursan. Specifically, our FPR I-Beams, C-Channels, angles and roofing products were used in the project.

The total production capacity of all the stations in the project is 238,000 cubic meters per day

Result:

The project was completed in 9 months. It offers alternative technologies and systems that adds to the project’s unprecedented achievement. Furthermore, electrical consumption was reduced to 3kWh/m3.

Articles and industry information:

- Statistics Denmark – Construction key figures (www.dst.dk)

- Construction industry statistics

- Safety in the building and construction industry

- Glass fibre – Designing Buildings

- Civilworld – Updates in civil engineering, architecture finishes, building construction, Environmental Engineering (vincivilworld.com)

Looking at figures from the Danish Energy Agency about lost time incidents over the last six years, slips, trips and falls are the most common working accidents (37%). We can help to reduce this trend with our non-metallic construction materials. Read more about our frp structural profiles and safety products here.

Explore our Non Metallics Solutions

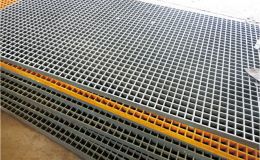

GRP Gratings

GRP/FRP gratings are as strong as conventional steel grates. They are available with an efficient non-slip surface, which gives you an excellent reason to change your steel grates eventually.

GRP Profiles

Whereas traditional construction materials like concrete, steel, aluminium and timber have only one strength, pultruded profiles have several advantages. That makes using them a particularly cost-effective solution.

Stair Treads

Stairs are a high-risk area when it comes to slipping or falling. If there is the slightest risk of an accident happening on a staircase, we recommend that the steps are secured. Our GRP fiberglass stair treads are lightweight – and strong, and an ideal alternative to conventional steel grating, concrete etc.