GRATINGS

Real Safety Contact Info:

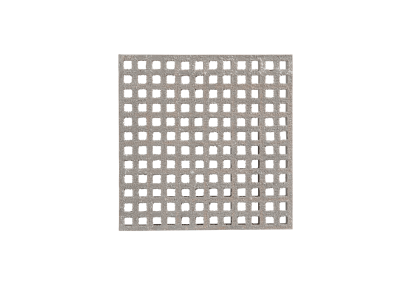

GRP Non-slip gratings

Real Safety’s non-slip gratings are designed to provide excellent slip resistance.

The obvious places to install fiberglass non slip gratings are: Stairs, walkways, landings, ship decks, bridges, production lines, chemical rooms, helidecks as well as any other place using grating flooring, where galvanized steel grates have traditionally been used. That makes them an ideal alternative to normal steel grates.

Our non-slip gratings are the only ones on the market to be certified and produced in the EU.

Due to this particular certification, they are also approved for use on Offshore Units for the specific Classification of Steel Ships, where fire criteria is extremely tough.

What are the benefits?

These non slip grp/frp gratings do not rust, corrode or deteriorate over time, which saves time and money on maintenance costs. Other benefits include:

- Enhanced safety – The grating surface is designed to provide a high coefficient of friction, which helps to prevent slips, trips and falls.

- Durability – Designed to withstand heavy use and exposure to the elements, making them a durable and long-lasting solution.

- Low maintenance – Easy to clean by high pressure water and do not require painting, sandblasting or replacement.

- Non Conductive – A safer alternative to steel grates in settings where electrical conductivity is a concern.

- Cost-effective – Non slip gratings are lightweight and easy to handle, transport and install, which can save time and money during the installation process.

Need some help or got a question? Check out our FAQs where you’ll find answers to most questions. If you can’t find the answer you’re looking for, please contact us!

Visit our YouTube Channel where you can subscribe and view product videos.

Superior anti slip properties

Light and easy to handle

High strength

Resistant to corrosion

Customizable

Non slip fiberglass gratings can be used in a wide range of settings and applications due to their numerous benefits, specifically where there is a need for a durable and slip-resistant flooring.

- Industrial and manufacturing facilities

- On landings

- Ship decks

- Bridges

- Production lines

- Helidecks

- Chemical processing plants

- Marine environments

- Oil and Gas industry

- Commercial buildings

- Food processing facilities

- Our gratings are designed to provide superior slip resistance even in harsh conditions. Traditional steel grates, on the other hand, can be slippery when wet, posing a safety risk.

- It is made of fiberglass and resin materials that are highly resistant to corrosion. Traditional steel grates can rust and corrode over time, which weakens the grating and poses a safety risk.

- They are significantly lighter than conventional steel grates, which result in lower installation costs and less strain on workers.

- They are not affected by UV radiation, so they do not need to be painted or treated with protective coatings.

Slips, trips and falls are a leading cause of workplace accidents and cost employers billions of dollars each year in lost productivity and business. In fact, the second leading cause of unintentional injury-related death, is falls.

According to the Bureau of Labor Statistics, over 1,000 workers die each year as a result of a slip, trip or fall and countless other mild or serious injuries resulting in days away from work. It is therefore of utmost importance for companies, organisations and institutions to understand the hazards.

If accidents happen due to a lack of safety measures on a walkway or areas in which people walk or work on, a company may be held liable for the injuries and damages suffered by the injured party. This can result in significant legal and financial consequences for the company, organisation or institutions, including:

- Lawsuits

- Fines and penalties

- Increased insurance costs

- Damage to reputation

Slips, Trips & Falls — Occupational Health & Safety (ohsonline.com)

KEY BENEFITS

The main benefit of our grp gratings is their superior slip resistance, which provides a safe walking surface in a variety of environments and conditions. Other benefits include:

- Made from high-quality glass fibre

- Slip resistant, even in a very slippery conditions

- We can modify and cut as required

- 10 years warranty – no maintenance

- Approved for use on Offshore Units and for the classified of Steel Ships where fire criteria are very touch

- Quick and easy to install

- Extremely light – about ⅓ of the weight of a steel grate

- As strong as normal steel grates

- FRP offers similar load bearing capacity as steel does

- Easily cut on site

- Ergonomically correct and comfortable to stand on

- Corrosion and chemical resistant

- Non conductive

- Available with a yellow “nose” which improves visual safety

If you have a risk area that may need a safety upgrade, please contact us.

Frequently Asked Questions

If you can´t find the answer you are looking for here, please contact us.

Please view our installation and cutting guide for Grating here.

Installing non slip grating is easy. It might also require that the product is cut to size on size. That is easily done by following our installation guide.

Cutting grating is similar to working with wood, with some slight differences. To obtain clean, precise and good quality cuts, it is recommended to use diamond tipped circular blades of the type that is used for bricks.

Our grating is a no maintenance product.

Regular cleaning will keep your stair treads free of debris and looking new. Products are easily cleaned by high-pressure water or steam – or just a normal broom.

NOTE: Do not use steel brushes or chemical cleaners on the surface.

Our grating usually last much longer than the minimum 10 year guarantee we offer.

It depends on the area and specifications. Contact us today! We would be more than happy to quote a price for you.

Non slip gratings are generally considered to be sustainable due to their durability, low maintenance requirements, and resistance to corrosion and degradation. In terms of reuse, these safety gratings can often be removed and reused if they are in good condition. They can also be cut and reshaped to fit different applications.

For recycling, the process for GRP is not yet widely established and the technology for recycling is still developing.

GRP non slip grating is available with an efficient non-slip surface. That makes them an ideal, value for money alternative to normal steel grates – and a perfect walkway grating option.

Real Safety gratings are made from a mixture of fiberglass and resin, which are moulded into a patterned grid shape. The combination of resin matrix and fiberglass reinforces and creates a lightweight, durable and corrosion-resistant material that is well-suited for use in harsh environments. Other characteristics include:

- Extremely light – about ⅓ of the weight of a steel grate

- Anti slip top surface – GRP gratings have a slip proof surface that offer excellent slip resistance

- We offer GRP gratings in standard colour grey ( RAL 7004), or any other colour combination.

Surface choice:

- Grit Top

- Concave Top

- Covered Grit Top

Several factors must be taken into consideration when choosing the right gratings to ensure safety, compliance, durability and cost-effectiveness of the product – including:

- Determining load capacity

- Slip resistance required

- Determining the size and shape needed

- Installation method

- Determining the environment and surface

- Traffic volume

Fiberglass non slip grating is available with an efficient non-slip surface. That makes them an ideal, value for money alternative to normal steel grates – and a perfect walkway grating option.

If you have any questions or want to know more about our anti-slip solutions, contact us today!

Other anti-slip solutions

Anti-slip step cover

A quick and cost-effective way to upgrade slippery stairs is to use Real Safety’s anti slip step covers. Safety covers will slip proof the area – but more importantly, the anti slip steps will prevent accidents from happening in the first place! Read more about our step covers.

Anti-slip stair tread gratings

These are pre-formed, GRP stair treads that replace existing stair covers. They are as strong as steel grates, low weight and corrosion free. Furthermore, they are 100% maintenance free and therefore offer great ROI. Read about our stair tread.

Anti-slip landing covers

Landing covers provide a slip-resistant surface on landing areas, such as the top or bottom of stairways and landings. They are made from high quality GRP – and come in four different colours and two surface grit options (extra coarse / coarse). Read about our landing covers.