Benefits of using GRP Composite materials

The role of GRP Composites in construction

The Construction sector is one of the biggest markets for Glass Reinforced Plastic (GRP) globally. It’s also known as Fiber Reinforced Polymer (FRP). An increasing number of architects, engineers and builders are now using GRP for a variety of building, infrastructure and for refurb projects and the trend is accelerating. Project range from refurbing existing structures to full-scale use for new projects – I.e. as reinforcement in concrete, bridge decks, modular structures, formwork, and external reinforcement for strengthening and seismic upgrades.

What makes GRP unique?

GRP Structural pultruded profiles are manufactured by combining a resin matrix with a fibre reinforcement. This is formed and cured in a continuous process creating a product of extraordinary strength and resilience.

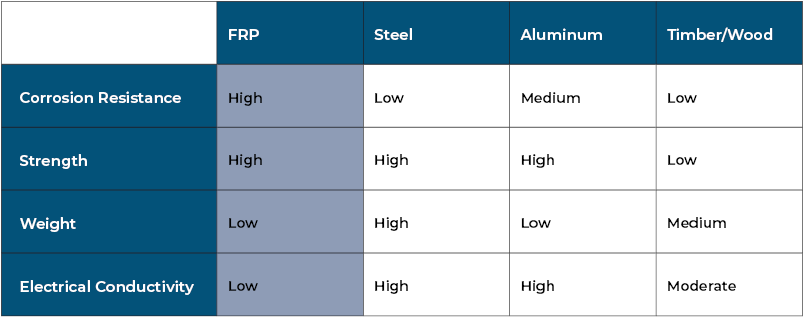

Key advantages of GRP vs Steel:

Strength

- Compared to steel, GRP Composites has equal or better strength simply because it has higher impact resistance than steel.

- It is gram for gram stronger than steel and aluminum with compressive and flexural strength.

- It is up to 3,3 times more rigid than timber.

Cost

- In harsh environments steel has a short life span due to corrosion etc.

- High installation costs due to material weight, galvanization and manpower is also associated with steel.

- GRP, on the other hand, is lightweight, requires only basic tooling and can be assembled on site at no additional cost.

- GRP has a much longer service life – requiring less maintenance and replacement.

- Overall cost benefits exceed steel equivalents

- Lower installation cost: up to 57%

- Low maintanance cost – FRP Year 1-5 : 0% Steel Year 1-4 3% & Year 5: 10%

- Significant reduction in manpower / hours needed – up to 20% less

Safety

- Construction sites are high risk environments. With GRP you don’t have to worry about structural integrity, durability, shock hazards or corrosion.

- GRP/FRP has low thermal conductivity and zero electrical conduction – and therefore safe to handle and able to retain reliability and performance properties in varying environmental conditions.

Durability and sustainability

- GRP Composites do not corrode and therefore, it has a longer service life than steel.

- It can handle direct exposure to acids, brines, oils, and many other common corrosives.

- GRP is also resistant to a broad range of chemicals and unaffected by water.

- It has been proven that GRP composite recycling is more environmentally friendly compared to steel in terms of energy consumption, making them a more sustainable substitute.

All our pultruded construction materials are also manufactured in accordance with CTI 137 Standard

FRP/GRP Composites case study: Water Desalination Project

In 2019, we successfully supplied a range of profile materials for a project in Saudi Arabia. In this project, several of our non-metallic GRP solutions were chosen for 8 plants in the KSA West Coast Desalination Plants project. Check our case study here.

If you have a construction project coming up or have questions about the possible application of FRP/GRP products, and how we might help, get in touch.